Eddy Current Dynamometers

- Eddy Current Dynamometers (ECD) cater to a wide range of requirements of Prime Movers from 10 to 100 BHP with RPM varying from 1500 to 5000 RPM.

- These are widely used for testing of engines in Production, R&D, and Quality Assurance.

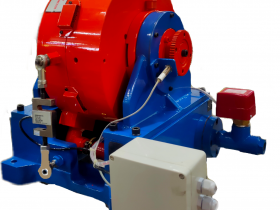

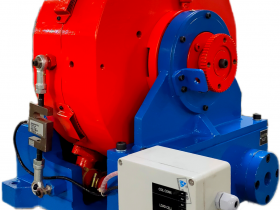

- Rugged construction and effective power absorption ensure long working life.

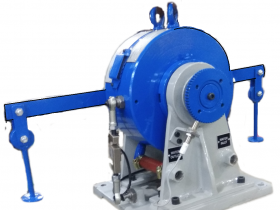

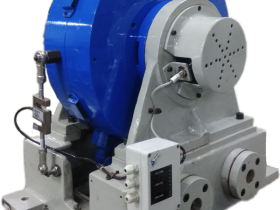

ECD compromises of : Rotor Shaft, Stator Casing, Base plate, Trunnion support, Excitation coil, load cell, cooling water flow lines, calibration lever, Hot Air Passages

Principle Of Operation : When ECU is connected to excitation coils, the current flowing generates magnetic field. When the toothed rotor is produced in the end wall of cooling chambers. This Eddy Current builds an opposing magnetic field and decelerates the rotor. Thus braking torque is transferred to load cell thru

Advantages : Easy of assembly, wide power range, disc rotor and hence low inertia, very high response to change in input signals, long life uses and long servicing intervals, easy maintenance due to less components, low downtime due to simple mechanical design.

Models : TME10, TME20, TME30, TME50, TME100, TME200 and TME300 are suitable fpr 10, 20, 30, 50, 100, 200 & 300 BHP capacities respectively.